Poly Carboxylate Ether products (Zetanul)

Poly Carboxylates are the newest water-reducing admixtures that are made of a unit structure. The Poly Carboxylate Ether is an organic polymer that is water-soluble and disperses cement particles, therefore, improving consistency as well as adjusting concrete setting. The ordinary water-reducing admixtures based on Lignosulfonate and Naphthalene are not used for high-strength concrete since they are not able to open cement particles in a low water-to-cement ratio. On the other hand, the excessive increase in these two admixtures leads to concrete setting problems.

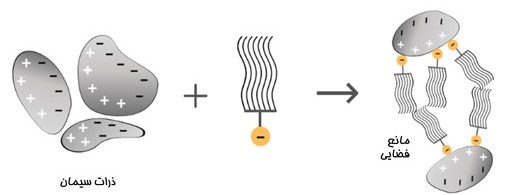

The mechanism of Poly Carboxylate Ether performance

The big cement agglomerates are formed when the water and cement are mixed, and since cement particles have a strong positive charge, by adding admixture, the particles are negatively charged because the admixture sticks to the surface of cement particles and leads to the dispersion of the particles; therefore, increases concrete efficiency and improves its consistency (Figure.1)

Different types of Poly Carboxylate Ether

The Poly Carboxylates are divided into two groups; the first group has high reducing properties and the second group has high slump retention.

The majority of the companies in Iran produce Poly Carboxylate Ether with high reducing properties, however, there are still weaknesses in producing Poly Carboxylate Ether with high slump retention.

The Hamgerayan production Company started to form a research group in 1390 and successfully produced superplasticizers based on the resin Poly Carboxylate Ether which was named Zetanul. This company produced a wide range of Zetanul products by relying on being knowledge-based, continuous efforts, and strong scientific support.

The Capco (Zetanul) is categorized into two groups in Hamgerayan Production Company:

It is important for Hamgerayan Production Company to fulfill the needs of all projects in our country.

Generally, there is a long distance between the batching plant and the factory (concrete dump site) in most projects. Also, it takes a long time to discharge concrete in some cases due to the geometry of the concrete section or structural complexity, or the limitations of concrete transfer tubes.

In some cases, producing concrete and its discharge will take about 2 hours.

Hence, the Hamgerayan Production Company (Capco) resolved the problem to a considerable extent by producing Zetanul resins with high slump retention properties.

This product is known as SRC in Hamgerayan Production Company. Some products of this brand include CapcoCrete SRC4030 and CapcoCrete SRC4060.

Contact the central office of the company at 02189331 to inquire about the price of the admixtures.

Also, the products of Zetanul resin with high reducing properties are supplied in the market with SPC brands and the most important products are CapcoCrete SPC251, CapcoCrete SPC10, and CapcoCrete SPC100.

Currently, less than 10 companies in Iran produce Resin Pole Carboxylate Ether.

Hamgerayan Production Company is also a large company that produces concrete admixtures.

The selling Poly Carboxylate Ether product of Hamgerayan Production Company in the field of slump retention is CapcoCrete SRC4060 and CapcoCrete SPC100 (Figure.2) has been the best seller in the field of reducing properties.

The effect of Poly Carboxylate Ether on the properties of the fresh and hardened concrete

Reducing water

The superplasticizer admixture based on Poly Carboxylate Ether can reduce over 30% of concrete mixing water. Also, more amount of mixing water can be reduced by increasing the cement content in an equal water-to-cement ratio.

Reducing the procedure of slump drop

The consistency drop has been significantly reduced by producing Zetanul admixtures based on SR since the drop can be controlled to a great extent by delaying the Tricalcium silicate (C3S) phase of the cement.

Consistency

The efficiency of the concrete is highly increased by reducing the concrete mixing water in an equal water-to-cement ratio and by adding a certain amount of the aforementioned Poly Carboxylate Ether plasticizer to the concrete mix.

The slump test (Figure.3) is generally carried out to measure the increase in efficiency. Also, the time of adding an admixture can affect the amount of the used admixture and its efficiency. it is noteworthy that the admixture must not be added to the dry cement or aggregates directly to reach higher efficiency.

Concrete air

The unprocessed Poly Carboxylate naturally produces air bubbles by being added to concrete therefore, it is necessary to add a suitable defoamer that is compatible with the Poly Carboxylate and has a good performance to control the amount of air entering the concrete.

Separation

To improve the efficiency, using the Poly Carboxylate to reduce the water of the mix design will not lead to separation with a proper mix design. The excessive use of Poly Carboxylate is the main factor of separation.

Compressive strength

The Poly Carboxylate will not affect the compressive strength directly however, the compressive strength can be significantly increased by reducing the water-to-cement ratio.

Durability

Using the Poly Carboxylate Ether to reduce the water-to-cement ratio can significantly reduce the permeability hence increasing the durability of the concrete.

Different uses of The Poly Carboxylate Ether in concrete

– The production and implementation of the reinforced and unreinforced concrete

– The production of RCC, SCC, HPC, and UHPC concrete

– The production of concrete with high consistency and a low water-to-cement ratio

– Different concrete casting in normal temperature

– Using in ready-to-use concrete with the water-to-cement ratio lower than 0.40

– The production of concrete with high slump retention

The Polycarboxylate Ether admixture can be evaluated based on the Iran National Standard No.2930-2 and 2930-1. Moreover, call Capco 02189331 for more information on the technical properties and the price of the water-reducing products (superplasticizers).