The production method of the fiber reinforced concrete and its usage

According to the conducted studies, engineers concluded that fibers have different capabilities and are impact resistant, absorb energy and increase the tensile strength of the concrete. In fact, the steel fibers inside the structure are complementary to the rebar and increase structural strength. The fiber reinforced concrete was first produced in the 1950s and has been used in the US and Soviet Union.

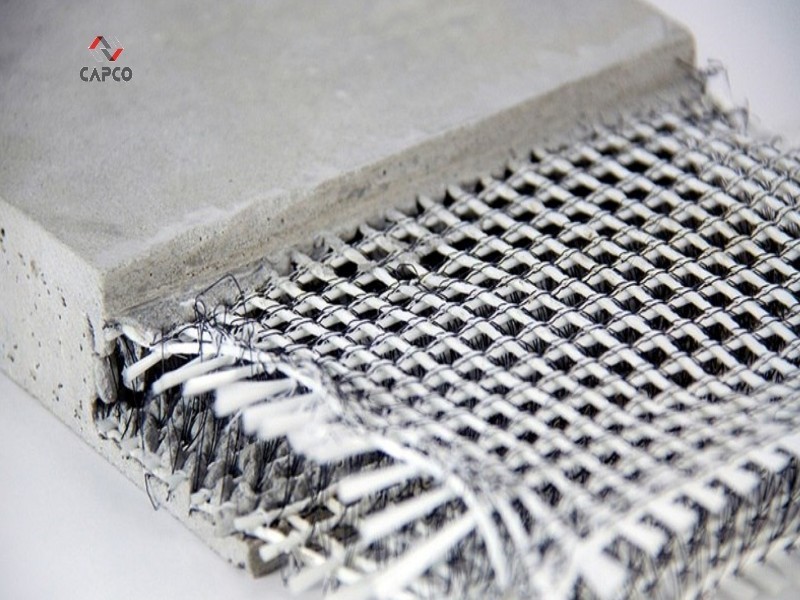

The steel fibers in concrete

By adding steel fibers to concrete, researchers found that using this product reduces the brittle matrix in current cracks of concrete, therefore, increasing its strength. Today, these fibers have been considered the most commonly used materials that are used along with the aggregates required for the concrete contents. Regarding the increasing use of this product in advanced countries, according to ACI, getting familiar with this type of concrete and its usage is of high importance.

What is fiber-reinforced concrete?

The FRC concrete is a composite in which the reinforcing fibers are used in its mix and therefore increase the tensile strength of concrete. This composite compound is continuous and monolithic in terms of structural properties and plays an important role in producing resistant structures.

High capacity and stability against strain or fracture are one of the most important properties of this product. These fibers include different types of polypropylene, glass, carbon, and steel which are more useful than other contents.

The different effect of this material on concrete lead to its geometric deformation and improves its performance in comparison with conventional concrete. The existence of these fibers increases the strength of the concrete against cracking and service life. Also, the concrete can have a strong performance against flexural, tensile, and shear forces.

The ingredients of the FRC

This innovative method to reinforce concrete has been well-known by the title “GFRC” which has a lot of usage. The material used in the FRC includes cement, water, polymer admixtures, different aggregates, allowable admixture, polycarboxylate (CapcoCrete SPC251), and fibers.

Each of these items plays an important role in increasing the cohesion, compressive and strength capabilities of concrete. The fine aggregates must have certain dimensions and follow specific standards so that the compound reaches desirable conditions. It is necessary to abide by the mentioned notes when producing this material so that the concrete reaches the ideal quality for use in specific environments.

The method of mixing FRC

Different methods are available to mix this concrete all of which seek for an ideal and practical compound. The methods of producing the FRC include the following items:

- The first method: first the fibers are combined with fine aggregates on the conveyor and placed inside the mixer. Then, other ingredients are added as well as some water to ease the mixing process.

- The second method: in this case, first the fine aggregates with big and small dimensions are placed in the mixer and made uniform. Then the fibers are added and combined with the aggregates. Next, cement is added to these materials. Finally, other concrete admixtures are added to this compound as well as some water to increase their quality.

- The third method: first the aggregates are poured inside the mixer along with water. The existence of water is to increase the strength of FRC. Then, the fibers, cement, and other admixtures are placed inside the mixer, respectively.

It should be noted that sticky fibers should be added to the compound in the last step so that it does not disrupt the mixing process.

The factors showing the quality of FRC

There are different factors to evaluate the quality of this type of concrete that need to be taken into consideration. The Hamgerayan Production Company (Capco) acknowledges the following items as the most important factors in the evaluation of the quality of Fibercap 12 material:

- The ratios of the used materials in the obtained concrete mixture

- The geometrical properties and appearance of the fibers used in the compound

- Evaluating the length ratio and diameter of fibers

- The mechanical anchorage and roughness and hardness of the surface of the fibers

- The physical properties and the type of fibers used in the concrete (steel, glass, polypropylene, etc.)

- The quality of raw material used to produce and mix FRC

The usage of the FRC

This type of concrete has special properties and different usages due to the material used in it. The price of the FRC varies depending on the used materials such as CapcoCrete SPC251 plasticizer and the type of fibers. The more quality of the raw material, the more efficiency and price the product will have. The most important usages of this type of concrete include:

- The construction of different types of hydraulic structures and dam construction

- The production of special floor covering for factories

- The production of different types of slabs and semi-precast sections used for other industries

- The construction of roads and high-strength tunnels

- The construction of bridges with different qualities

- The construction of different types of reservoirs and special tubes for transferring special materials

- The design and production of shotcrete using concrete

The advantages of using fibers in the concrete

The addition of fibers to concrete is one of the newest methods to increase the capacity and capabilities of concrete. This product has special mechanical properties like high compressive strength, high level of elasticity modulus, high elastic limit, high tensile strength, high stiffness, high capacity against fracture, cracking, etc. all of which lead to an increase in the advantages of using FRC.

The production of the Fibercap 12 and using it has been provided for users in the Capco Company. The most important merits of using this product include:

- The high strength of the FRC against abrasion

- High capacity against structural stresses within a long time

- Very desirable strength against impact

- Having tensile strength and high capacity against deformation

- Increasing load-bearing strength of the structure after cracking

- The capability to absorb energy in very large dimensions

- Having flexibility in different conditions using the CapcoCrete SPC251 plasticizer

Conclusion

Using fibers is one of the very new technologies to increase the tensile strength of concrete in different environmental conditions. The FRC has widespread usage and is used as an improved material in different structures.

The technologies used to produce this product have led to an increase in its capabilities and the quality of work increases by using FRC to a desirable extent. It can be said that the production of this product to be used in structures is cost-effective and its price is very suitable compared to the usage it develops.

Different conditions should be evaluated with high accuracy to increase the final quality of work. The possibility to produce the best fibers in the Capco Company has been provided for users. Moreover, FiberCap12 and different types of building chemical admixtures can be purchased from this Company. The phone number-021-89331- has been given to users to link the customers with the experts of the Company. You can call this phone number to consult with the experts of Capco Company and use the concrete in your buildings and submit your order. It is better to know the properties of this product and obtain enough